The Exchange, KU Edwards, Overland Park, KS :: 2017.

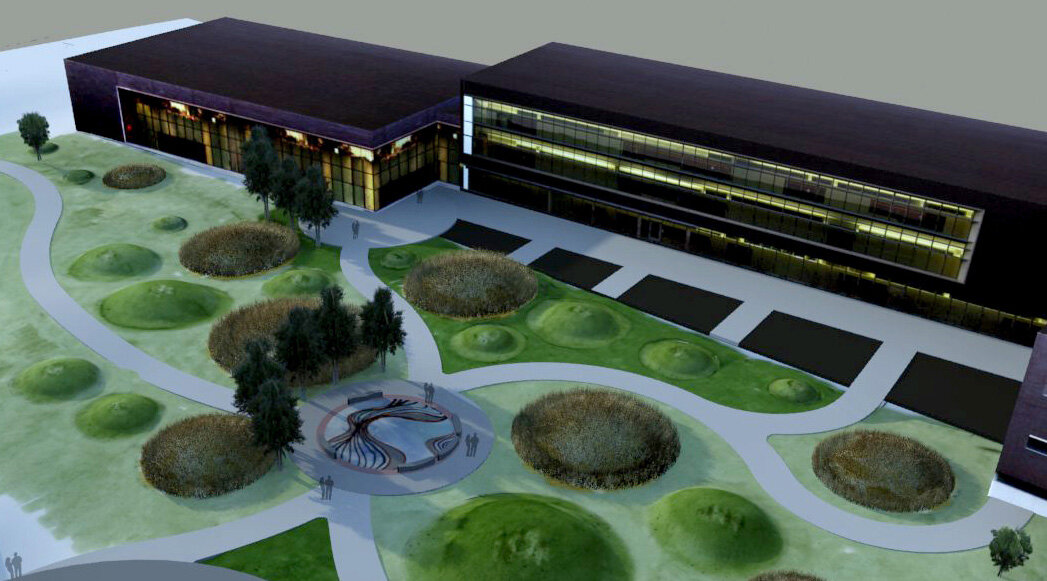

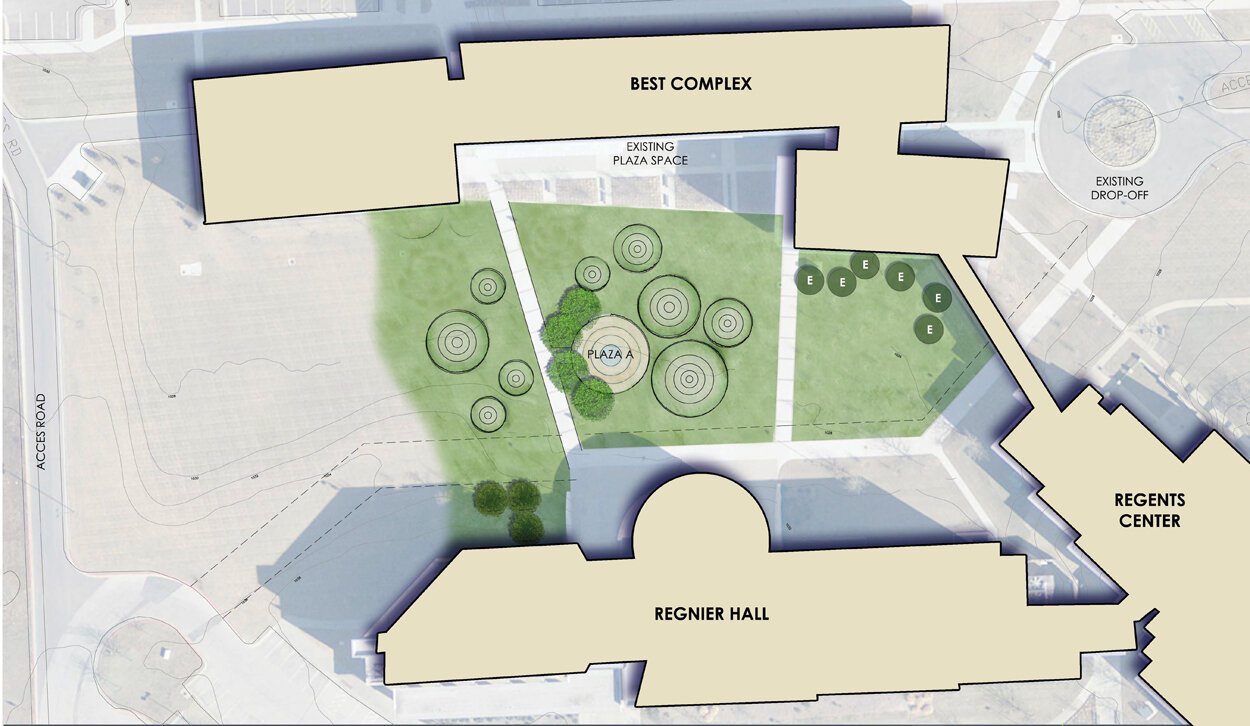

When we were first invited to create public artwork for KU Edwards, we inherited an extensive design that had been prepared by Olsson Landscape Architects, who were to be our collaborators on the project. After discovering the history of the Hopewell Exchange system and identifying our goal to create a more exciting and sustainable landscape on the campus green, we began to explore the possibility of grassy mounds and winding pathways, with a central plaza through which all would pass.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

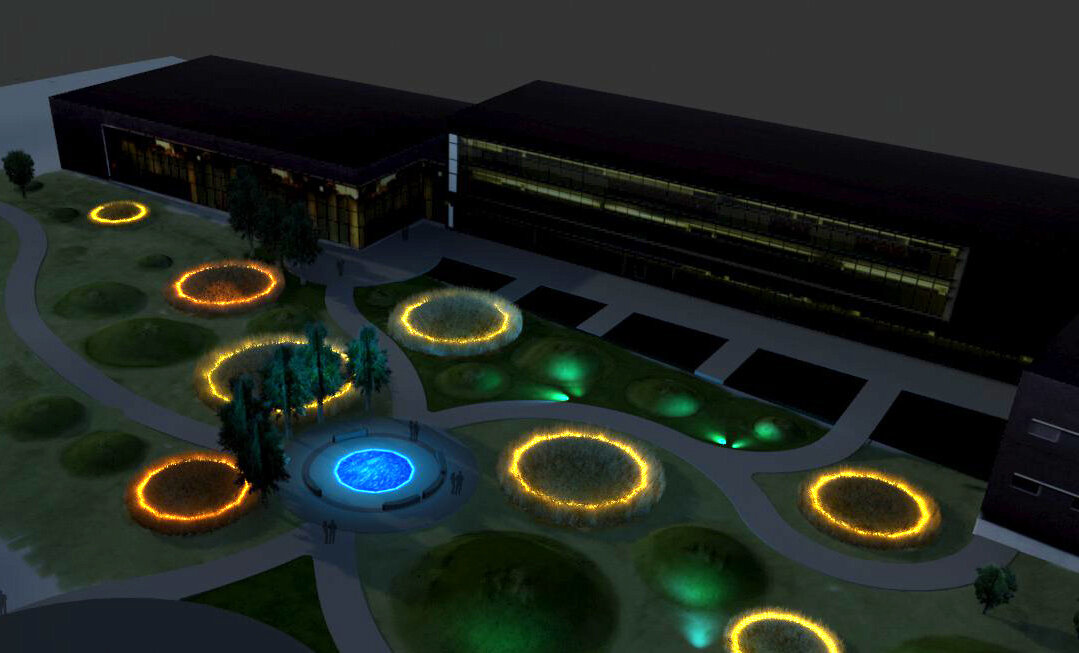

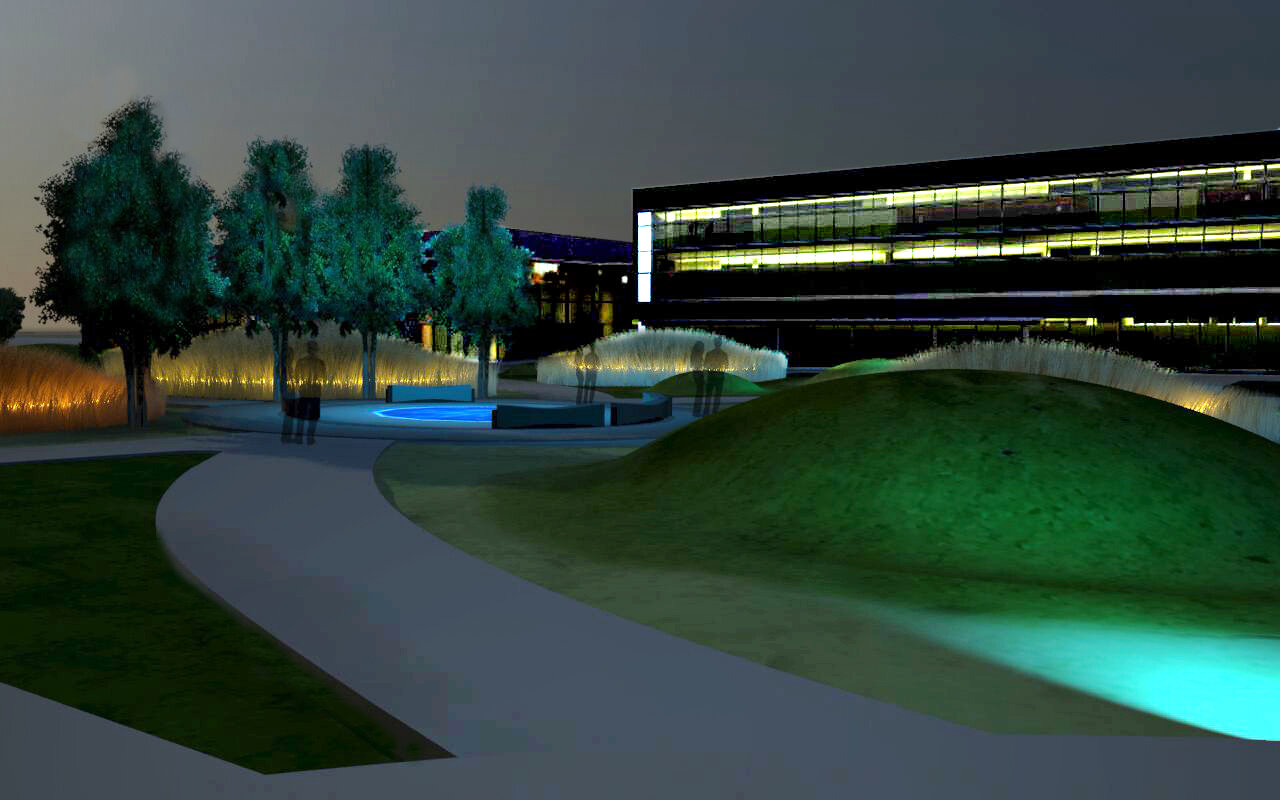

This design went through several iterations that included a compelling night view from inside the buildings, by means of lighting installed amid plantings of native grasses.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

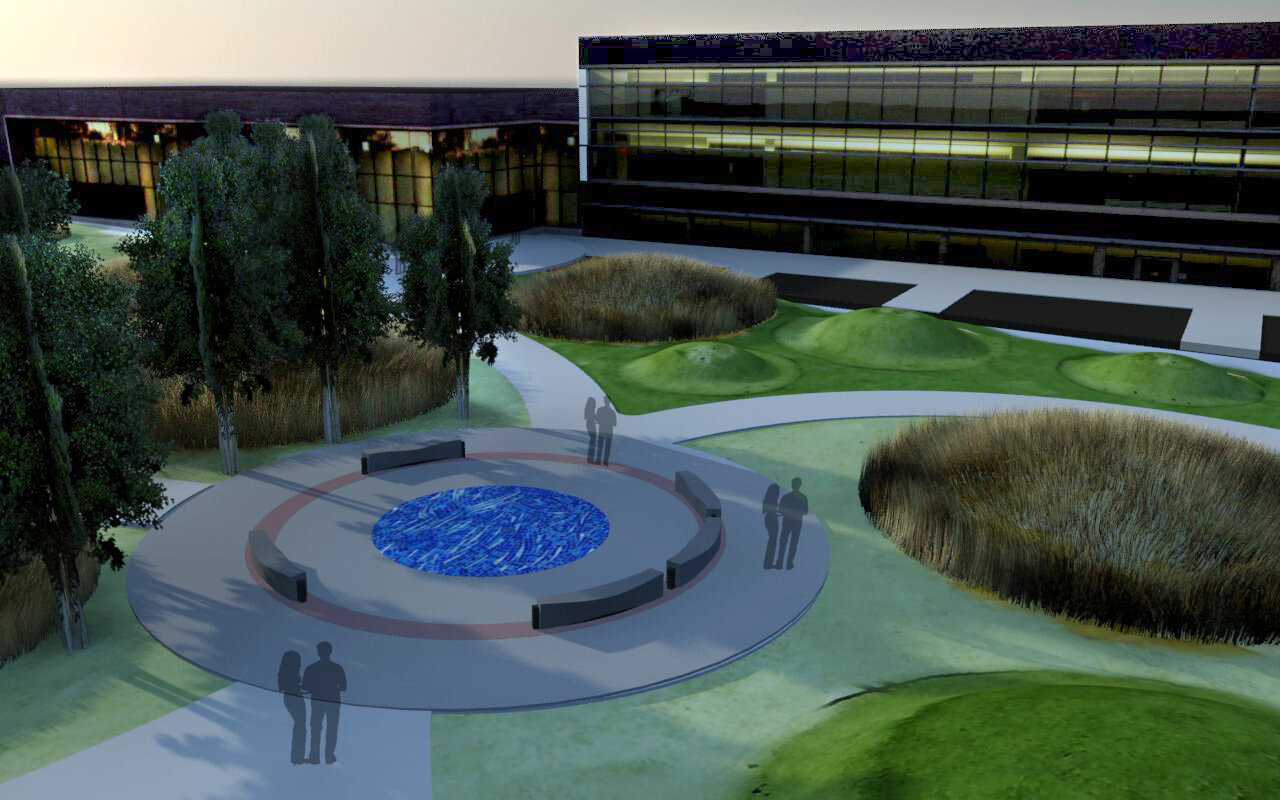

The plaza would include seating and shade trees, as well as some kind of mosaic tiling.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

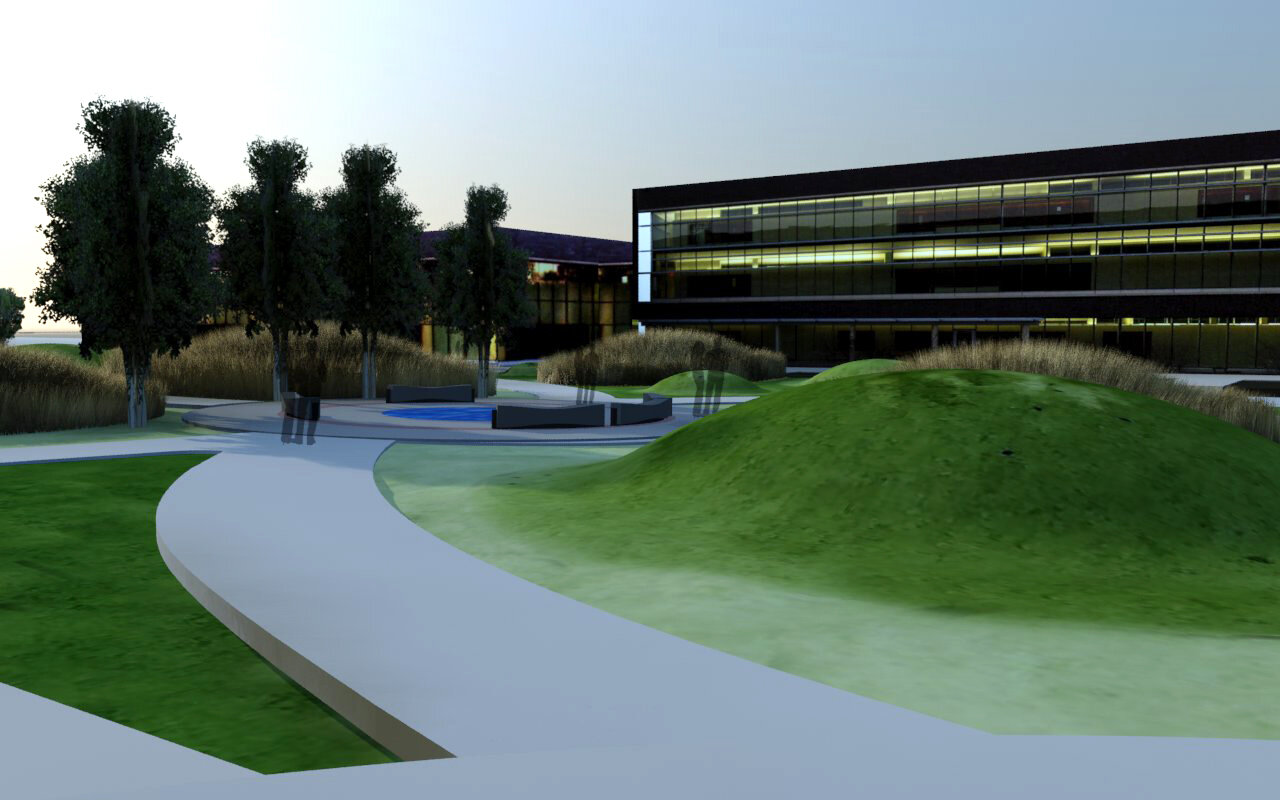

Not only would the mounds break up a flat plane and create an interesting space for both walking and sitting, but we envisioned that these could be places for audiences to sit during performances or events on the plaza.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

Soft and attractive lighting at night would create both welcome and safety.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

As the project progressed it became evident that the budget was more constrained than initially envisioned, and the mound and curving paths design was simplified – while still retaining the central plaza.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

Ultimately, as time passed and costs continued to increase, the only aspect of the design that remained was the plaza and shade trees.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

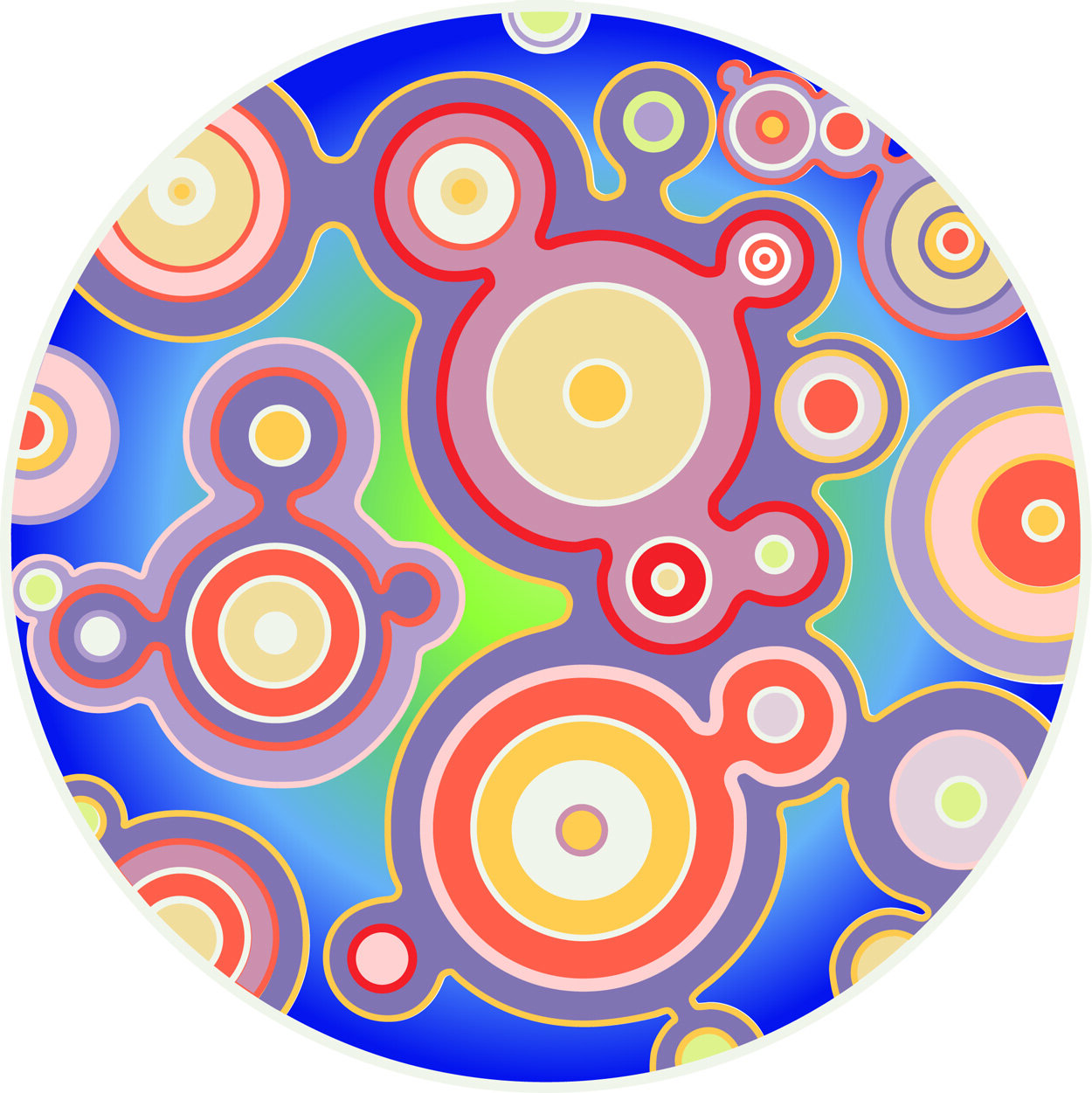

The design for the mosaic was hand drawn and then turned into a digital document. This allowed for many sequential color iterations, and created a means for estimating the quantities of tile that would be required.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

The mosaic was then assembled in our studio. It was created in pie-shaped wedges that were then assembled together, a process that was facilitated by mounting the tiles upside down on a heavy-duty, sticky, transparent backing.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

We used a large sonotube to transport the mosaic to the site. The entire sheet of tiles was rolled around the tube, which facilitated lining up the design correctly on the concrete pad.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

After the sheet was mortared to the pad and had dried, the plastic backing sheet was removed. The tiles were then cleaned and grouted, cleaned again and sealed.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

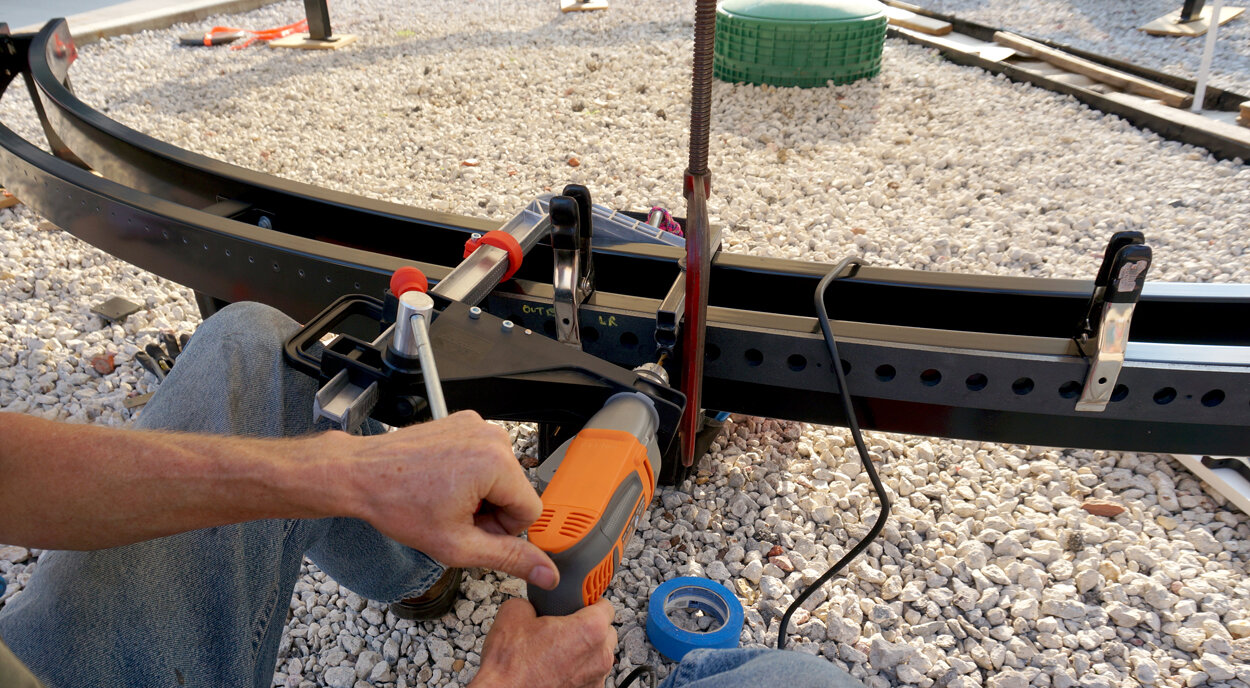

Bench construction began with the assembly of two rails of rolled square steel tubing onto supporting posts. The raw steel was subsequently acid etched and powder coated for weather resistance.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

Holes were then drilled precisely for mounting the bench slats. For easy transportation and installation the support rails had to be segmented and joined on site to make the complete form.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

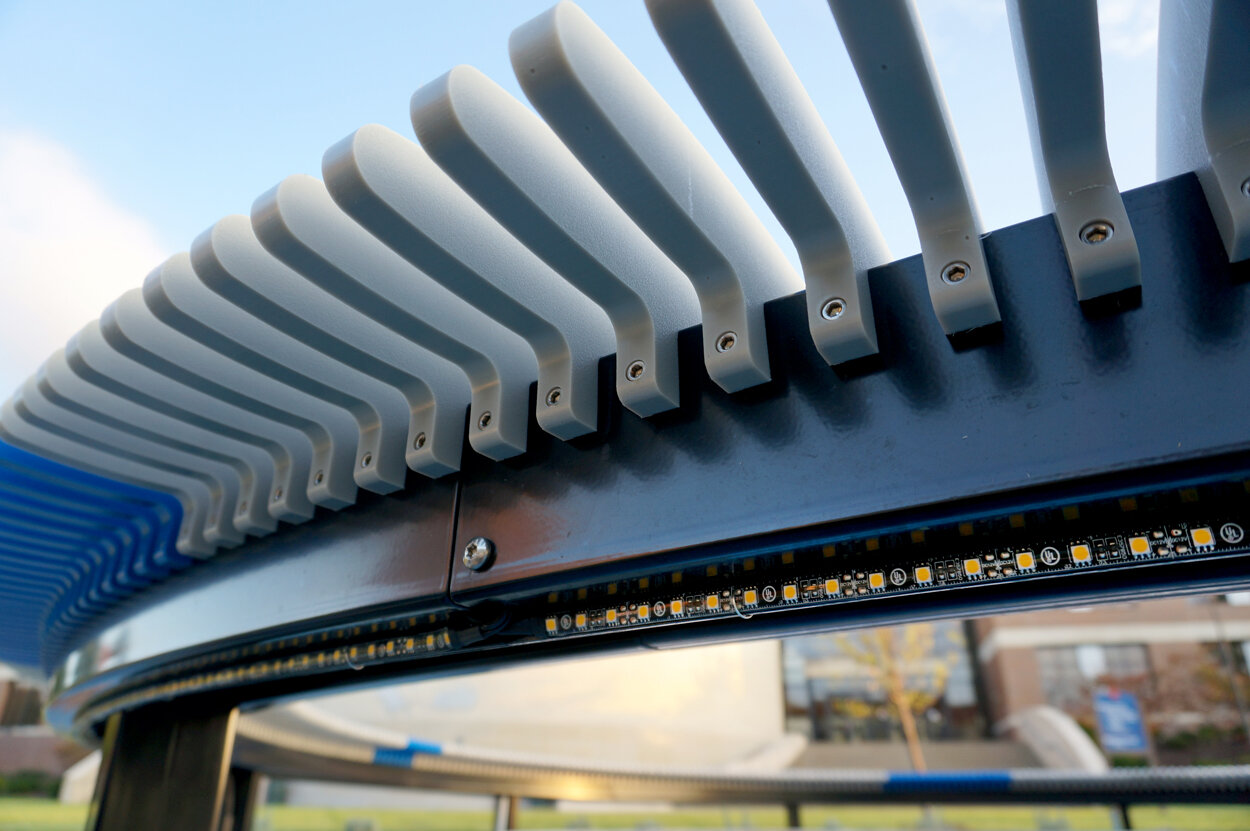

A view of the mounted slats from above. The material is recycled High Density Polyethylene (HDPE), and the pieces were custom cut on a CNC router in our studio.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

Detail showing the profile of the end-cap slat. A surprising amount of time was spent refining the shape of the slats so that they were both comfortable and elegant looking.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

Detail of the underside of the bench from the inside curve, showing slat attachments, power stub-up connections, and the lighting strips.

The Exchange, KU Edwards, Overland Park, KS :: 2017.

Detail of the underside of the bench from the outside curve.