Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

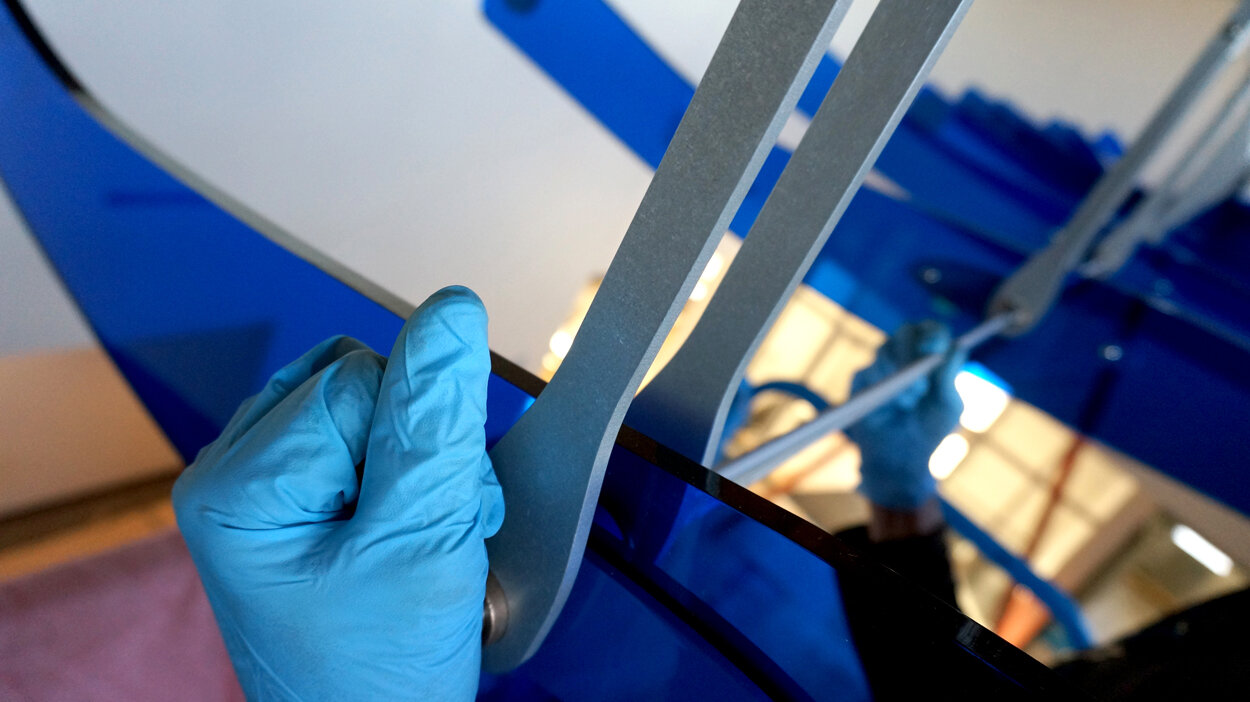

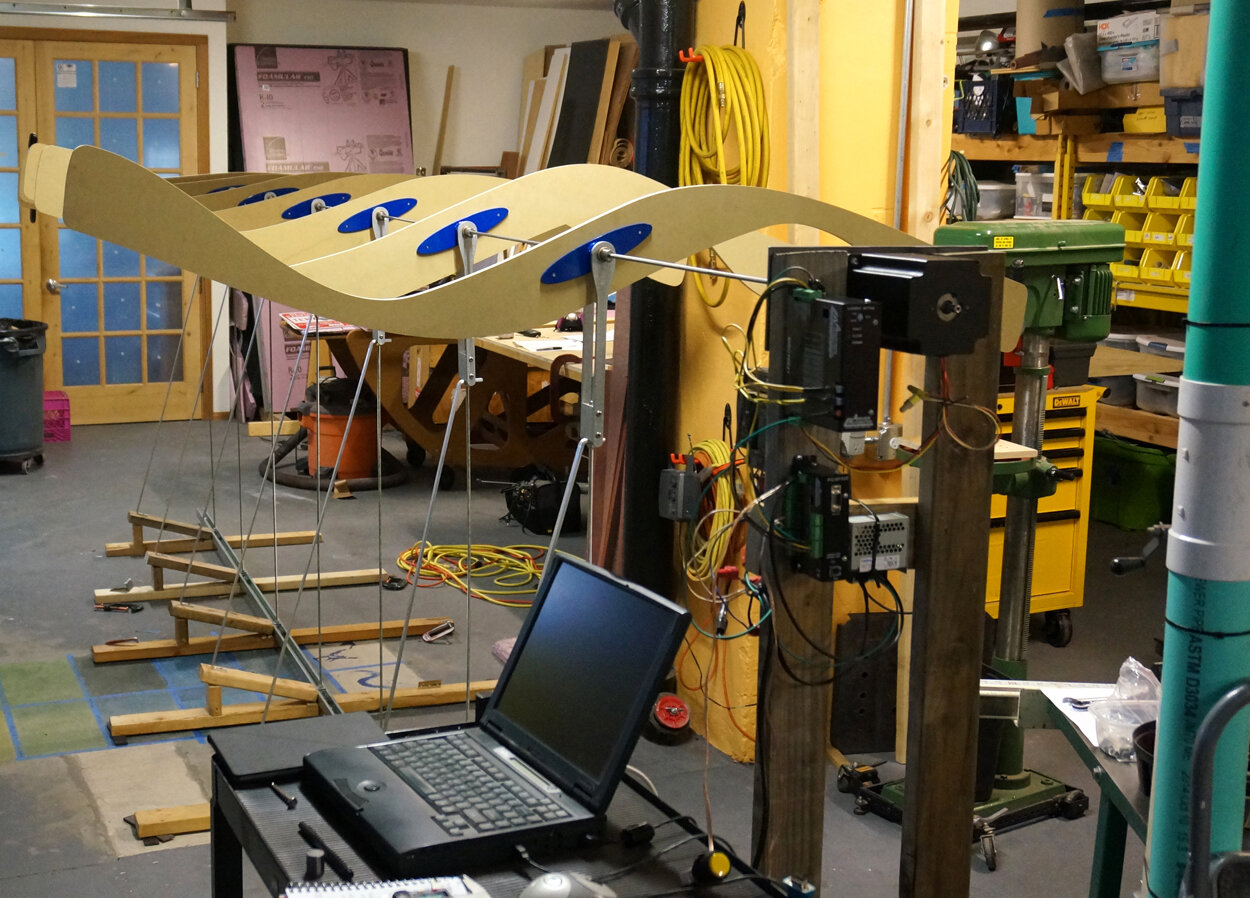

Initial studio tests were performed upside down, with the bracing facing the floor rather than the ceiling. These tests used fins made out of MDF to determine initial parameters such as spacing and shape of the sculpture’s elements.

Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

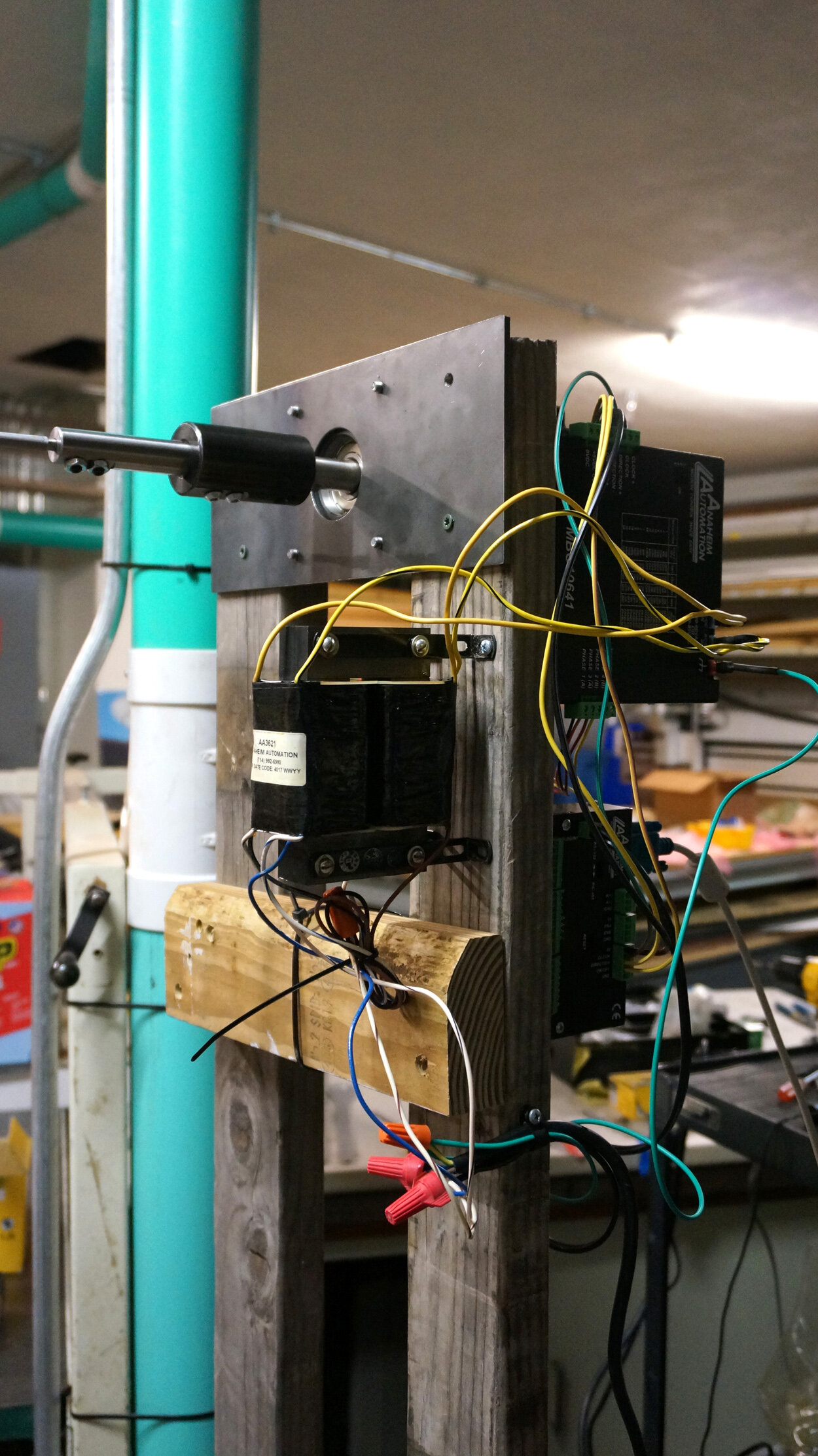

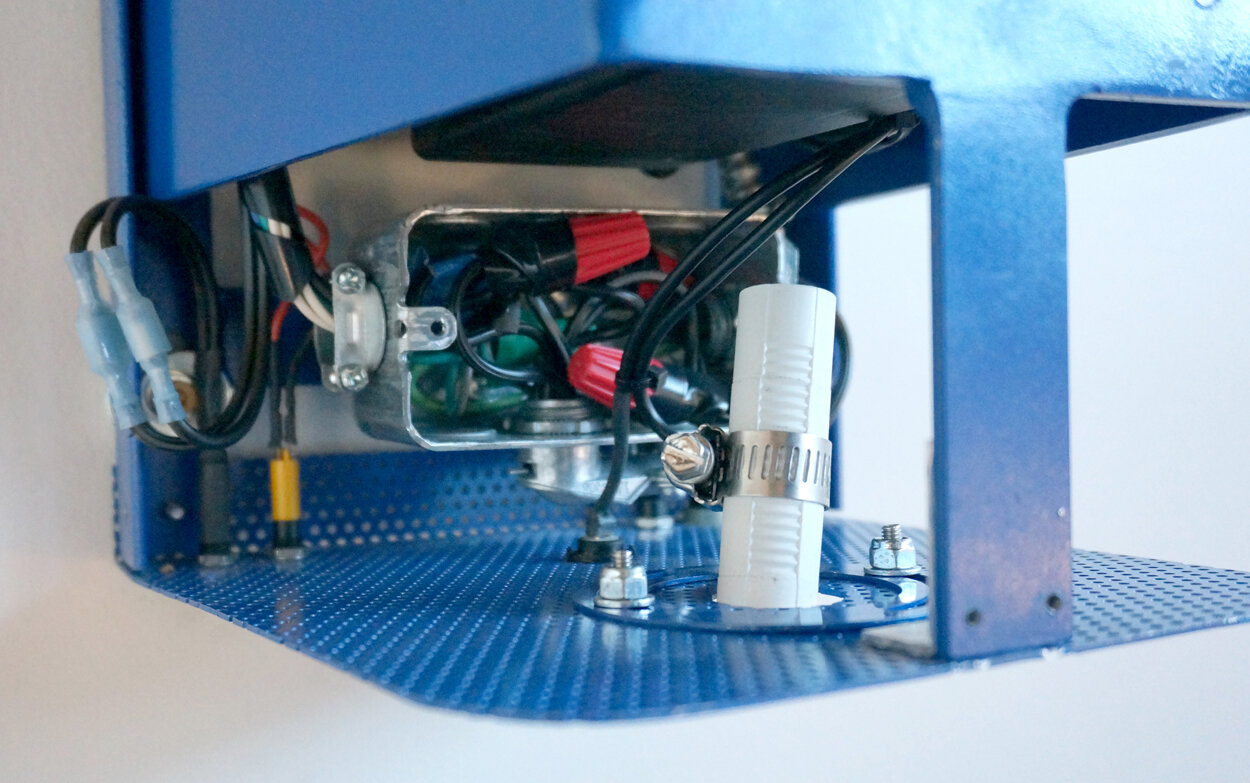

These are the elements of the controller, driver and motor assembly prior to packaging into a control box.

Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

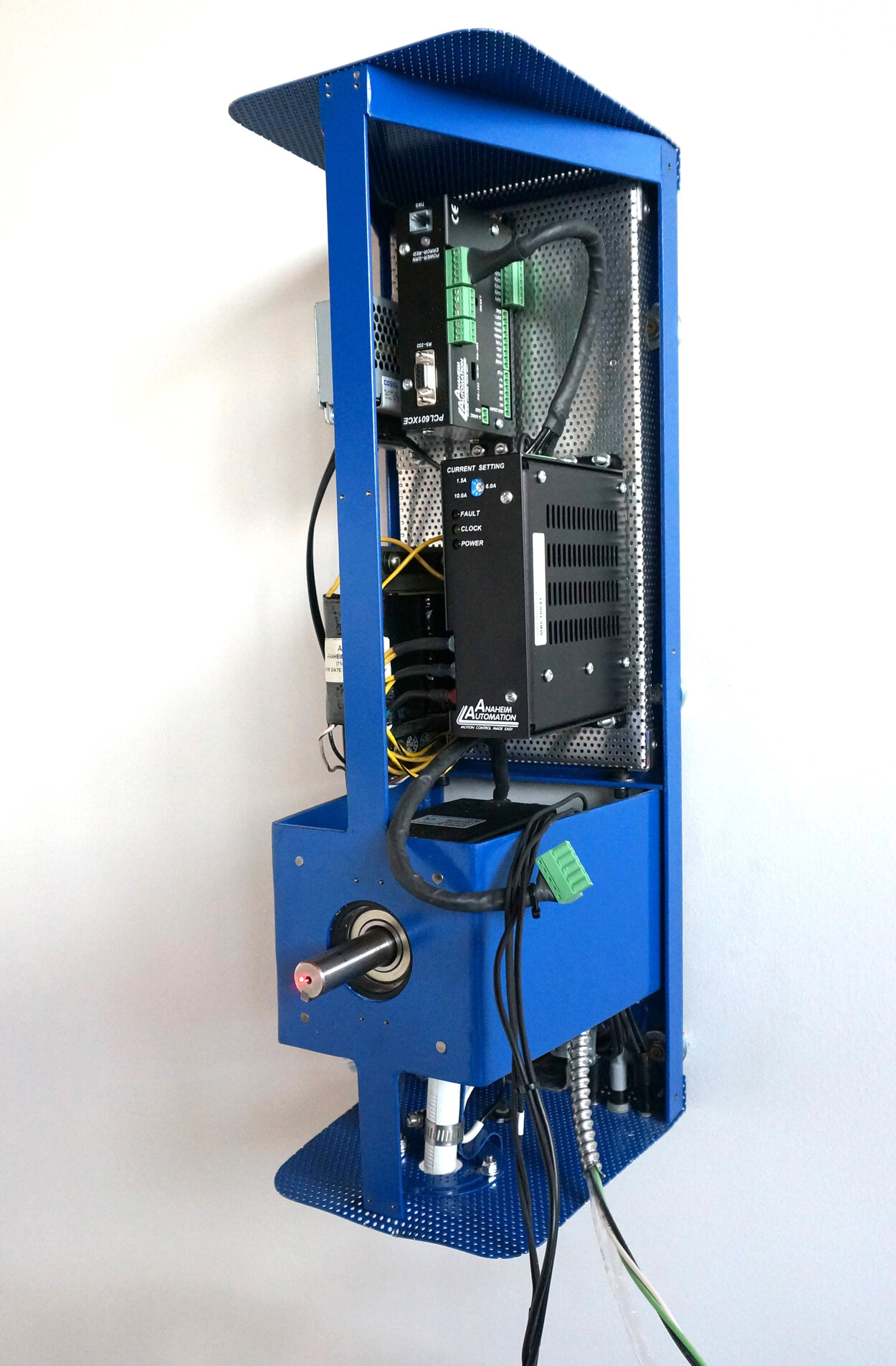

Front side of the same assembly showing where the shaft exits the stepper motor and connects to the sculpture.

Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

This is the structural frame for the control box, welded in our studio

Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

The internal form has been encased in a rectangular framework and painted. Here it contains the motor and sensor components.

Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

This image show the controller, driver and transformer mounted on a removable modular panel, which is then enclosed in the frame.

Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

Close up showing the controller and programming ports.

Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

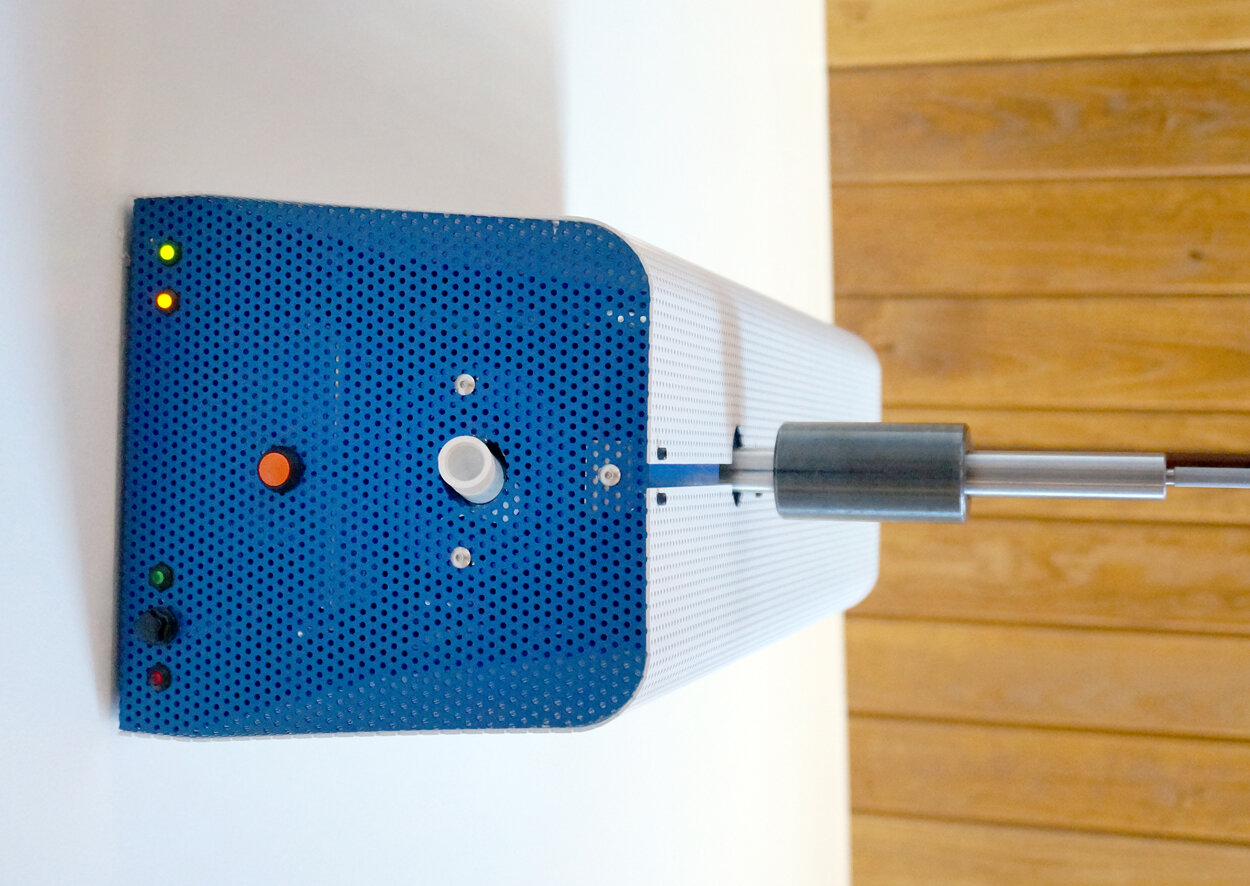

Close up showing the PIR motion sensor in its field-adjustable mount, angled to focus on visitors as they enter the main door to the observation area.

Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

The underside of the control box. The design incorporates diagnostic leds that indicate normal function of each subsystem. These assist with rapid identification of malfunctioning components if the system is not responsive.

Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

These are the ceiling mounts that were installed first on site. It was quite challenging with the sloped wood plank ceiling to ensure that vertical and horizontal alignment remained true down the entire length of the sculpture.

Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

Ceiling mounts seen from below. Each support shaft is slotted into a continuous channel installed in the ceiling by the General Contractor. This permitted us to fine-tune the spacing of the fin locations on site.

Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

Using a lift to install the prepared fin and pivot assembly units.

Coffee Creek Ripple Effect, Water Resource Recovery Facility, Edmond, OK :: 2018.

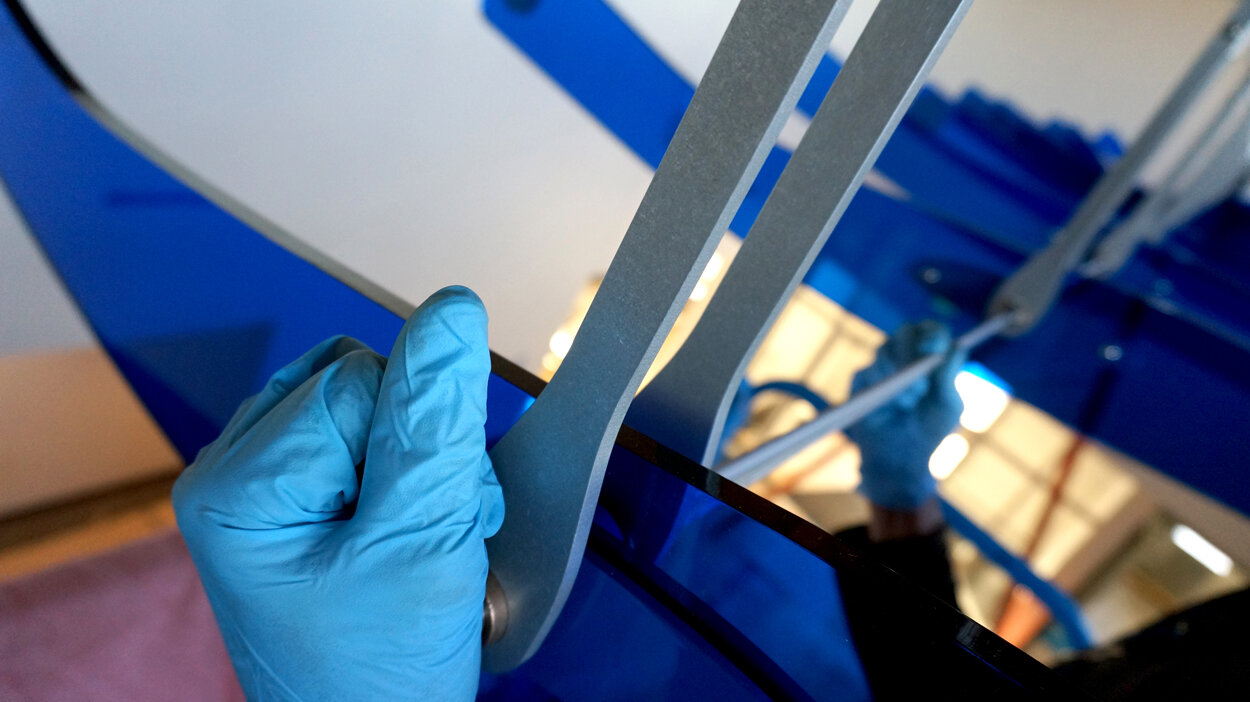

The fins required precise measurements between each unit, and careful torqueing as they were tightened down onto the connecting shaft. The fins then had to be cleaned, connected to the driving motor, and fine-tuned with a series of adjustments to ensure smooth and coordinated function. We returned after the bearings had worn in to make further small adjustments to the motion of the fins.