Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

This jig was designed to hot-wire cut the edge of each foam layer at the precise angle that had been determined via slicing up a CAD drawing of the final form.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

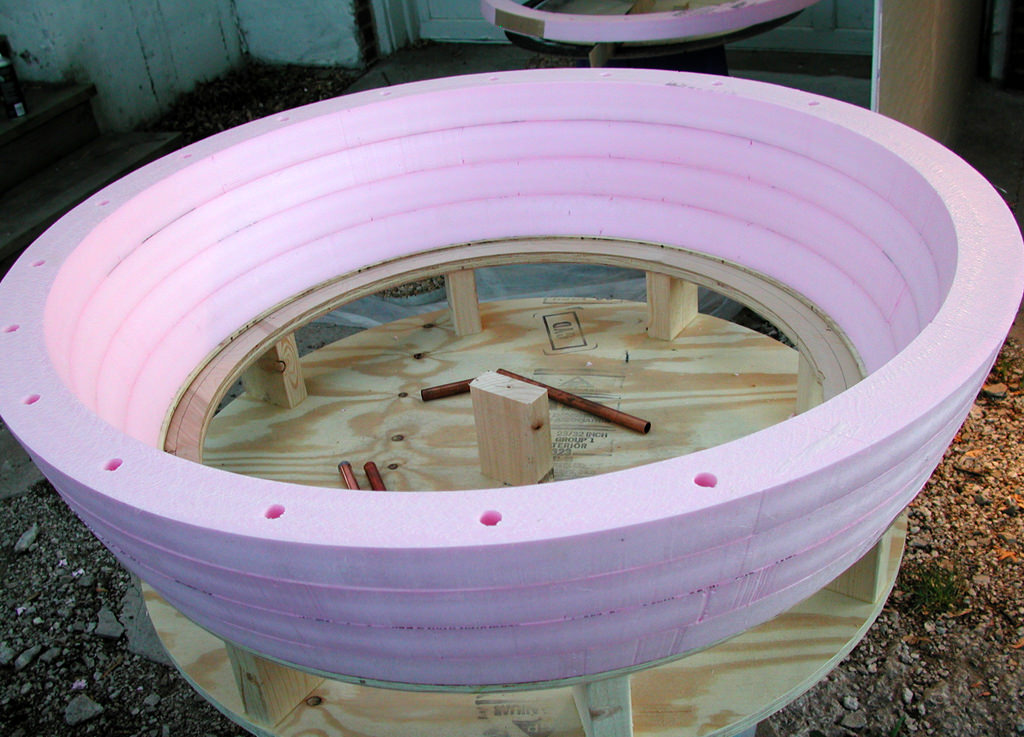

This is the base of the jig that was designed to cut channels through the expanded foam layers at accurate intervals.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

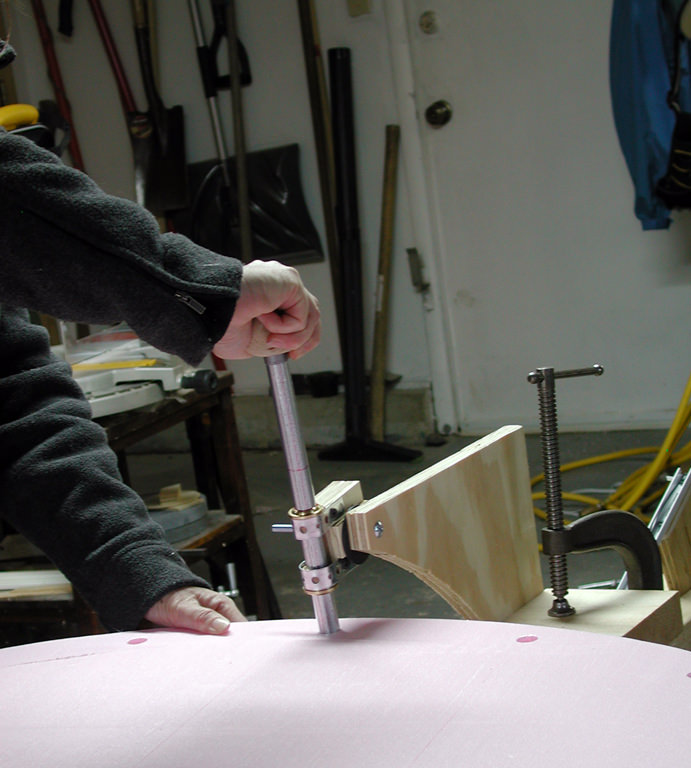

This is the top of the channel jig. It is being used to punch holes through each layer of foam. The channels were necessary for threading the wiring from the sensors to the controls that were placed in the base of the booth.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

When the discs had been cut into rings, they were glued together. We used lengths of piping to align the wiring channels and ensure that each slice was properly stacked on top of the one below.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

Though the edge of each ring was at the correct angle, each cut was a straight line, and so the exterior had to be sanded to create a continuous, smooth curve.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

After sanding, several coats of Aqua resin and pearl veil fiberglass were applied to the foam, and this then was sanded smooth.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

Coating the interior of the booth was a messy job, especially working overhead.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

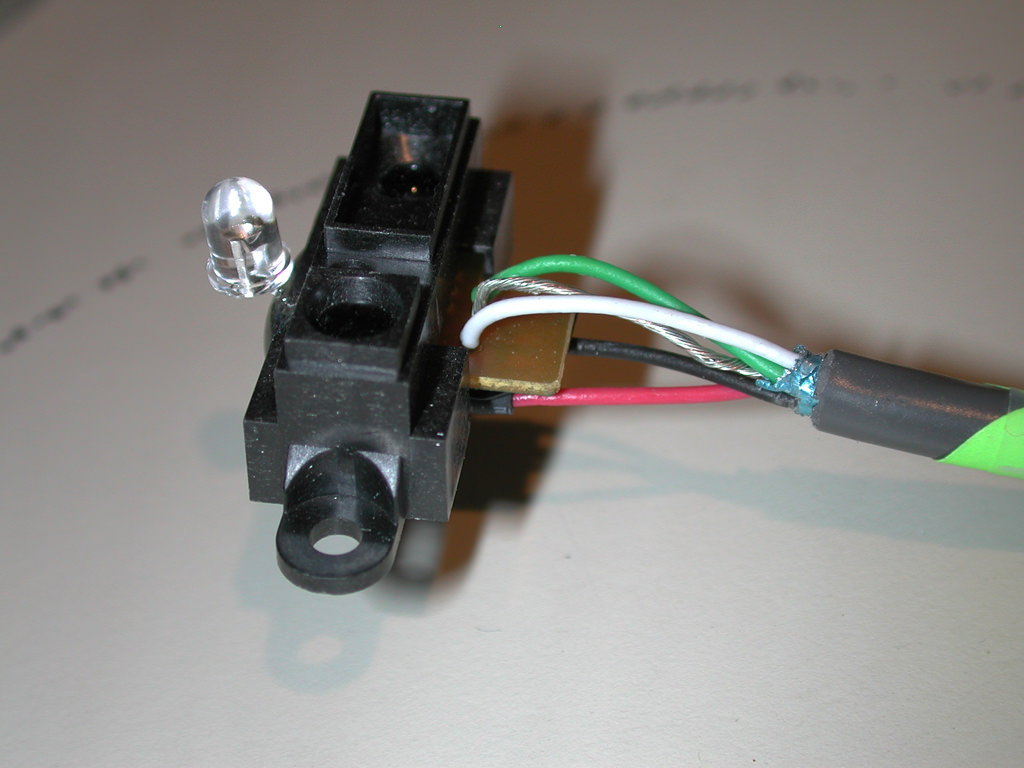

This is one of the sensors used for triggering the text files. It is a distance sensor because the initial intention was to have the words play at different speeds, depending on how far away a person’s hand might be. This, however, proved not to be possible with the computer speeds that were available at the time. The LED bulb was the sequence indicator built into each sensor unit for the “Follow the Poets” mode of operation.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

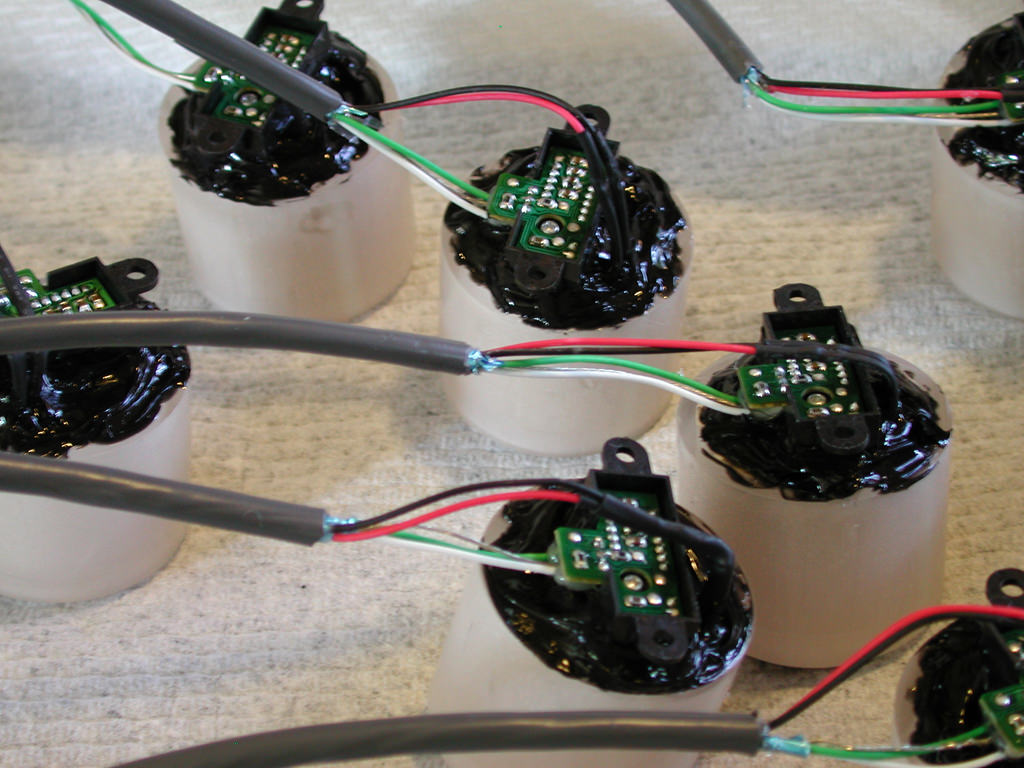

These lenses were made by embedding acrylic rods into tubes filled with Aqua resin and then polishing the ends.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

A distance sensor was then glued to the back end of each lens.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

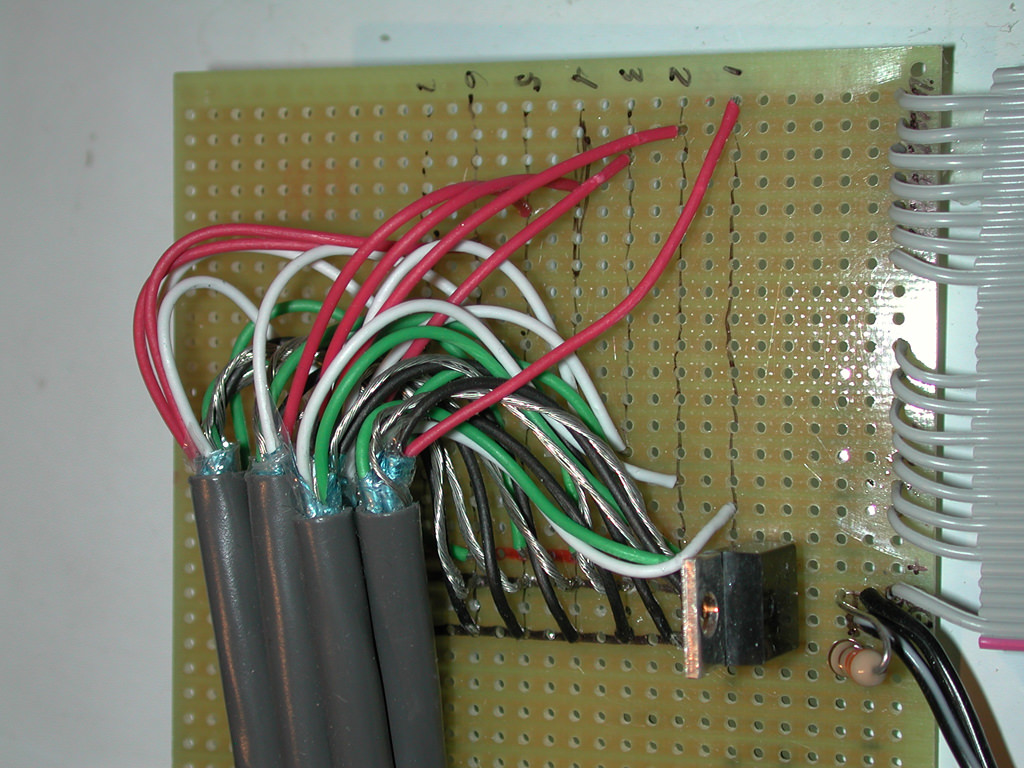

The wiring from groups of seven sensors was then wired into each control board.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

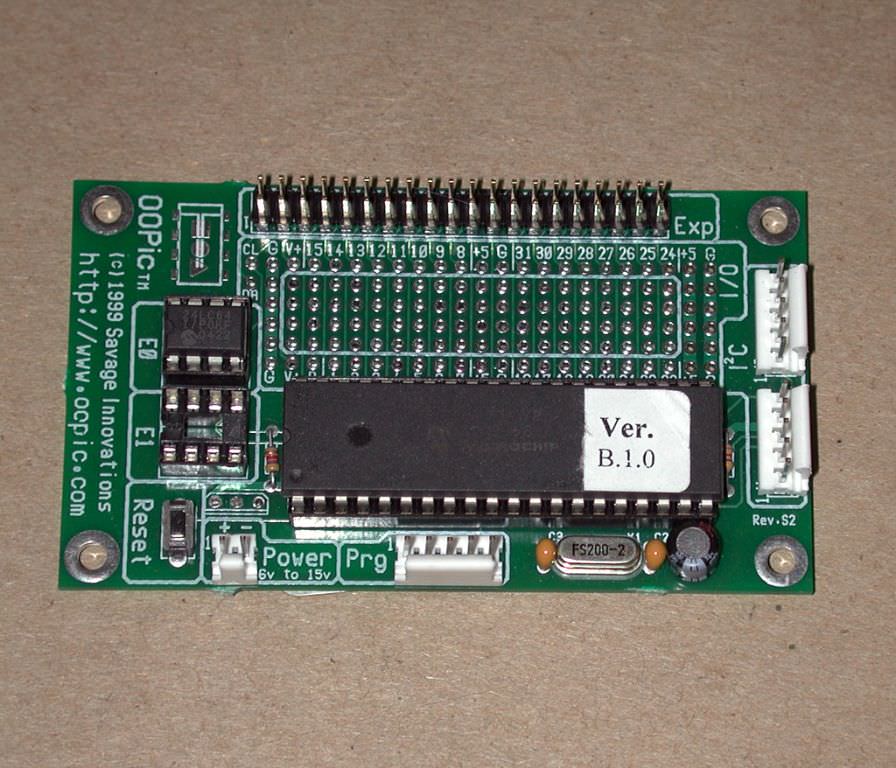

This is the Oopic microprocessor that was used for controlling the sensor inputs and routing them to a Max MSP interface.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

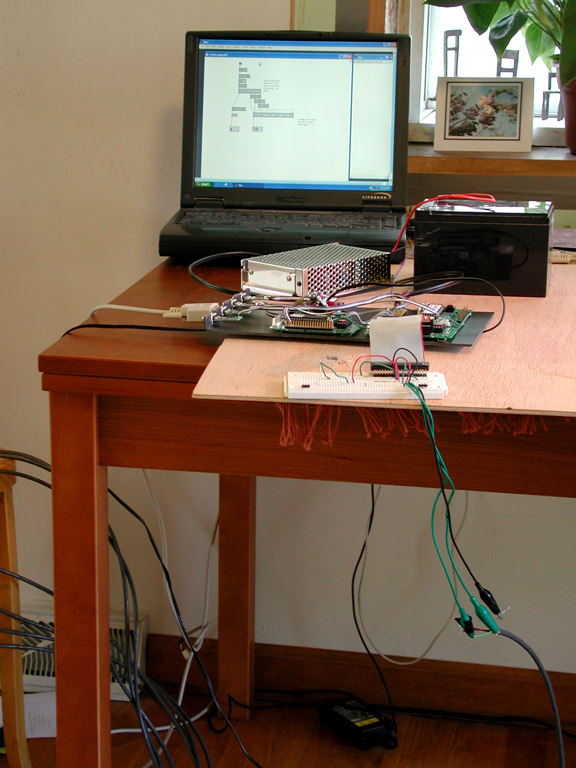

This image shows testing sensor inputs with Max MSP output.

Poetry Machine: 7’ 6” x 4’ x 4’. Expanded foam, Aqua resin, sensors, battery power, microprocessors, computer and sound systems, Seattle, WA :: 2005.

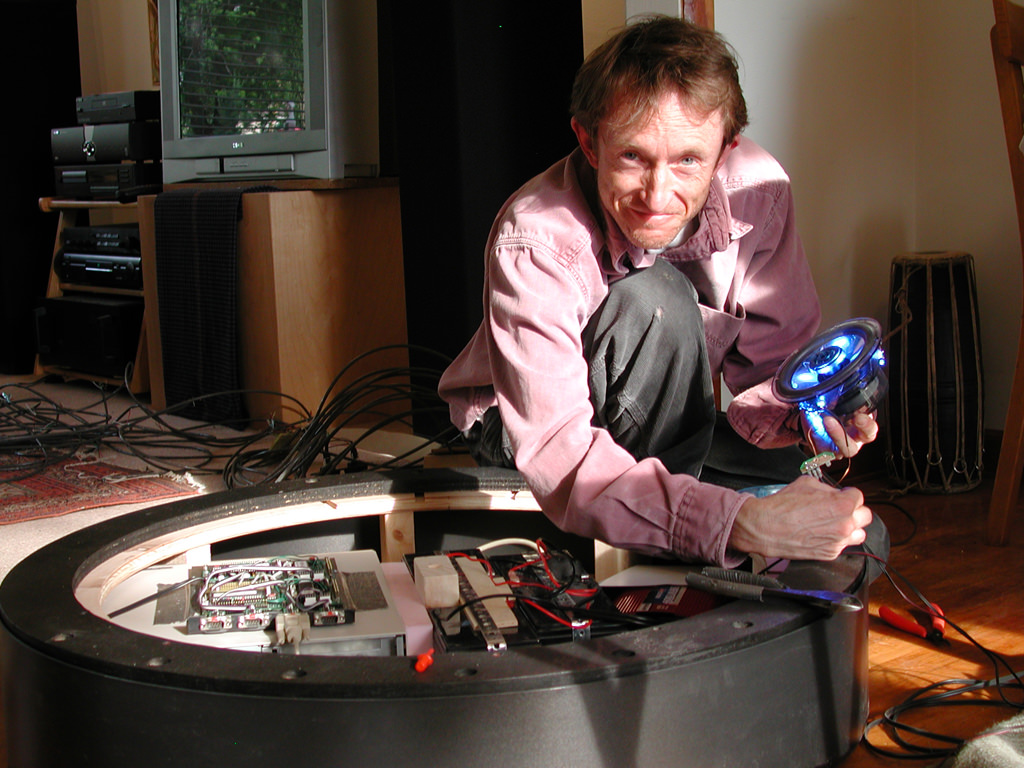

This image shows the computer, control systems and motorcycle batteries packed into the base of the booth. Leigh is holding the speaker that was mounted in the ceiling inside the booth. Its blue light illuminated the interior.