Ripple Effect: 3’ x 6’ x 150’ Acrylic fins, steel, aluminum, sensors, controllers and stepper motors :: 2009.

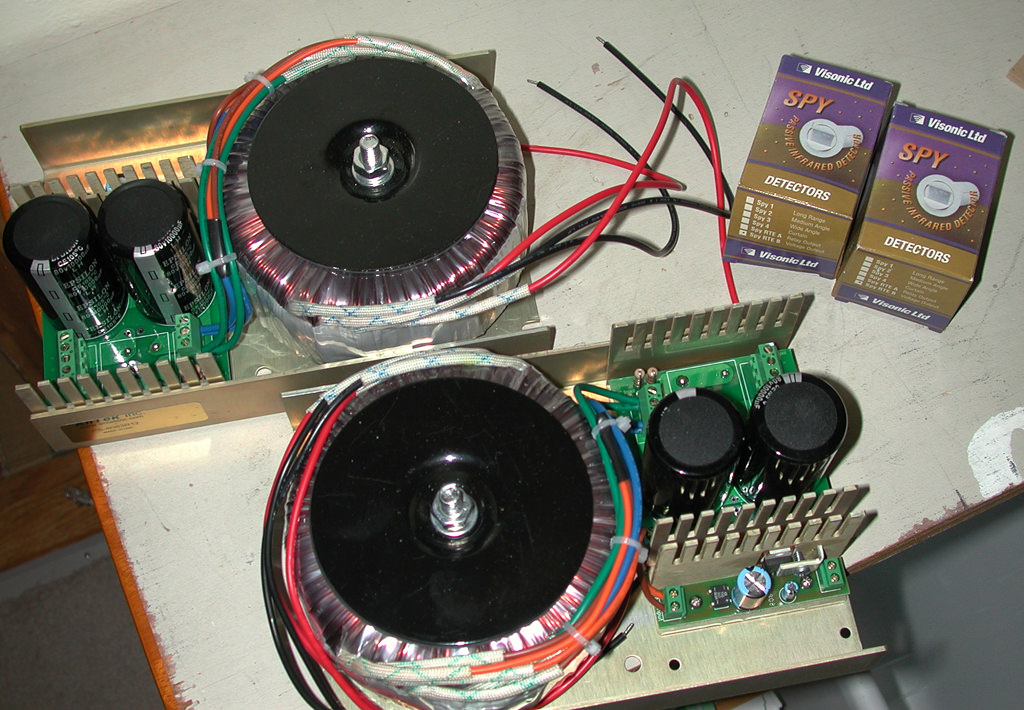

These are the transformers and sensors used in the kinetic Ripple Effect sculpture.

Ripple Effect: 3’ x 6’ x 150’ Acrylic fins, steel, aluminum, sensors, controllers and stepper motors :: 2009.

This image shows a sheet of aluminum on the bed of the CNC, which is cutting parts for the motor mounts.

Ripple Effect: 3’ x 6’ x 150’ Acrylic fins, steel, aluminum, sensors, controllers and stepper motors :: 2009.

CNC cut parts for motor mount, prior to assembly and painting.

Ripple Effect: 3’ x 6’ x 150’ Acrylic fins, steel, aluminum, sensors, controllers and stepper motors :: 2009.

This is a view from below the assembled motor mount showing the downward-facing sensor.

Ripple Effect: 3’ x 6’ x 150’ Acrylic fins, steel, aluminum, sensors, controllers and stepper motors :: 2009.

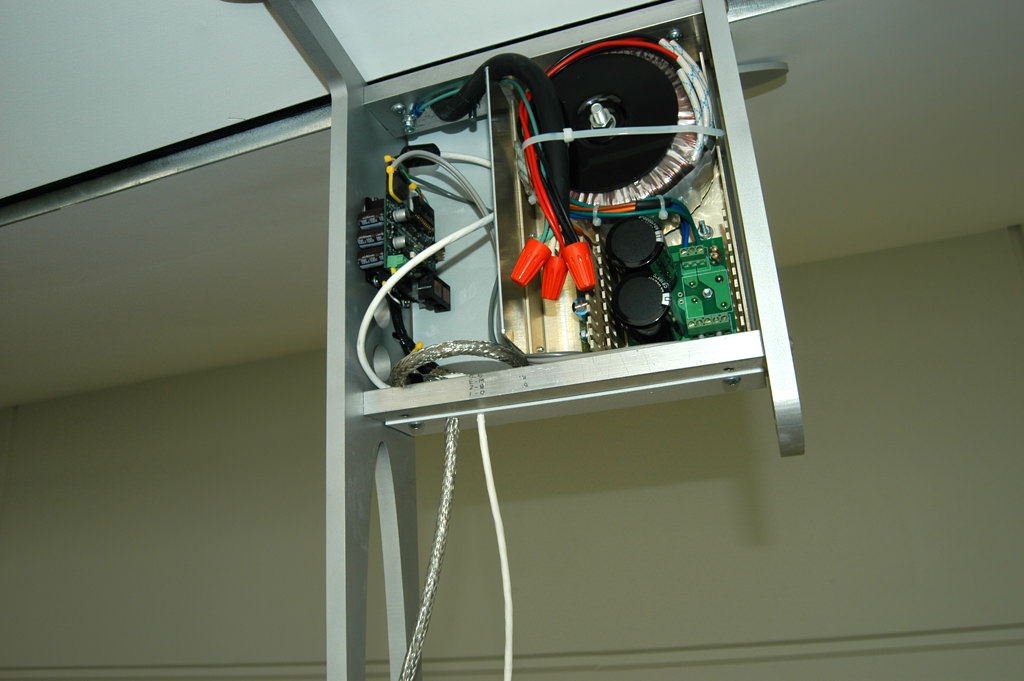

A view inside the control box, showing connections to the sensor unit.

Ripple Effect: 3’ x 6’ x 150’ Acrylic fins, steel, aluminum, sensors, controllers and stepper motors :: 2009.

A closer view of the motor and controls.

Ripple Effect: 3’ x 6’ x 150’ Acrylic fins, steel, aluminum, sensors, controllers and stepper motors :: 2009.

Here the acrylic fins are fitted with mounting hardware in our workshop.

Ripple Effect: 3’ x 6’ x 150’ Acrylic fins, steel, aluminum, sensors, controllers and stepper motors :: 2009.

This is a side view of the clamp plates that attach the fins to mounting hardware and each other.

Ripple Effect: 3’ x 6’ x 150’ Acrylic fins, steel, aluminum, sensors, controllers and stepper motors :: 2009.

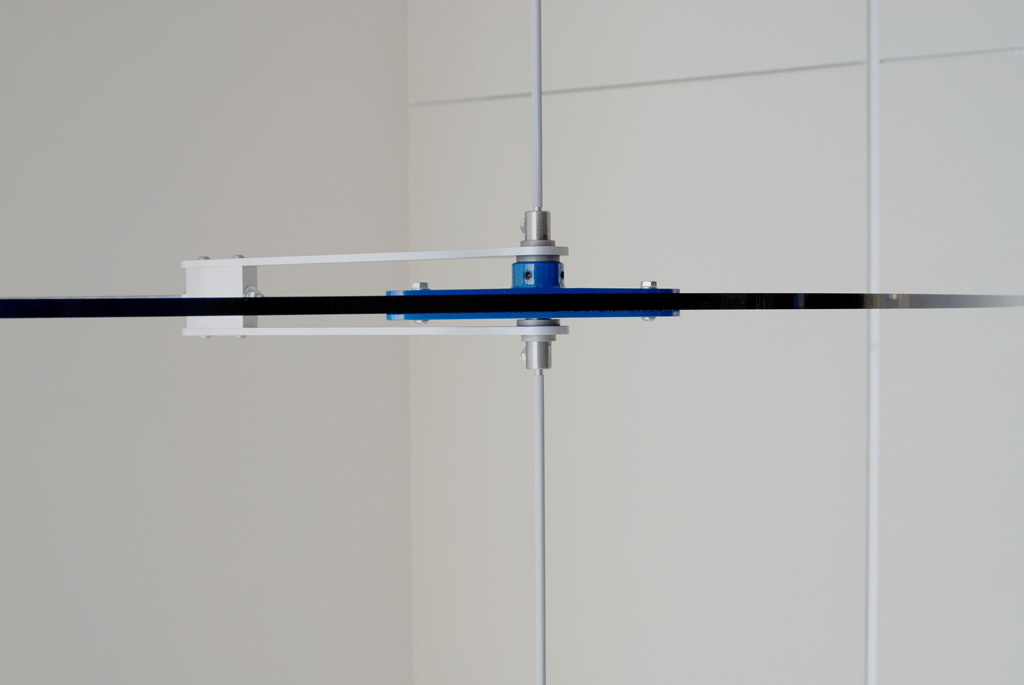

This is a detail of the blade connection system.

Ripple Effect: 3’ x 6’ x 150’ Acrylic fins, steel, aluminum, sensors, controllers and stepper motors :: 2009.

This is a detail of the ceiling mount and stabilization system.